Batch Code 101

Batch codes play a critical role in product production, serving as unique identifiers for groups of products manufactured under similar conditions. These codes provide traceability, helping businesses monitor production details, manage inventory, and ensure quality control. For consumers, batch codes offer transparency, enabling easy access to product information such as manufacturing dates and expiry details, reinforcing trust and safety in the supply chain.

What is a Batch Code?

A batch code, also known as a lot code or batch number, is a unique identifier assigned to a specific group of products manufactured or packaged together under the same conditions. It serves as a tracking tool, enabling manufacturers and distributors to trace production details, monitor quality, and address recalls if necessary.

Batch codes can take various forms, including alphanumeric combinations, serial numbers, or a mix of letters and symbols. For example, a typical batch code might look like "AB12345" or "20230101-L01," where the components indicate production date, location, or specific production line. The format often varies depending on industry standards or company preferences.

Why Use Batch Code?

Batch codes play a vital role in ensuring product quality and traceability across industries. Here are the key reasons for using batch codes:

- Product Tracking: Batch codes allow manufacturers to trace a product's production history, including its date, location, and conditions of manufacturing, ensuring that each item can be easily identified and monitored throughout its lifecycle.

- Quality Control: Batch codes capture critical details like production date and location, which helps maintain high-quality standards. If a defect is detected, they assist in quickly identifying and addressing the issue.

- Regulatory Compliance: By providing a clear record of production details, batch codes help ensure that products meet safety and compliance requirements, demonstrating their integrity and adherence to regulations.

- Efficient Recall Management: In the case of a recall, batch codes allow for swift identification of affected products, reducing risk and minimizing impact on consumers.

- Supply Chain Management: They streamline inventory management and optimize the flow of goods through the supply chain by offering detailed information about each product batch.

- Customer Communication: Batch codes help customers report issues accurately and assist businesses in resolving them efficiently.

By utilizing batch codes, companies enhance both operational efficiency and customer satisfaction.

Where Is a Batch Code Required?

Batch codes are crucial across various industries and for numerous products.

1. Industries That Use Batch Codes:

- Food and Beverage: Batch codes offer critical details about production dates and locations. They help ensure product freshness, streamline recall processes, and comply with health and safety standards.

- Pharmaceuticals: Required for identifying production batches to comply with stringent health regulations.

- Cosmetics and Personal Care: In this industry, batch codes are key for quality control, tracking production details, and addressing customer safety concerns.

- Aviation and Automotive Parts: Ensures the traceability of components for safety and performance.

2. Products That Require Batch Codes:

- Medications and over-the-counter drugs

- Skincare and beauty products

- Packaged foods, beverages, and perishables

- Industrial parts and equipment

Where to Find Batch Code

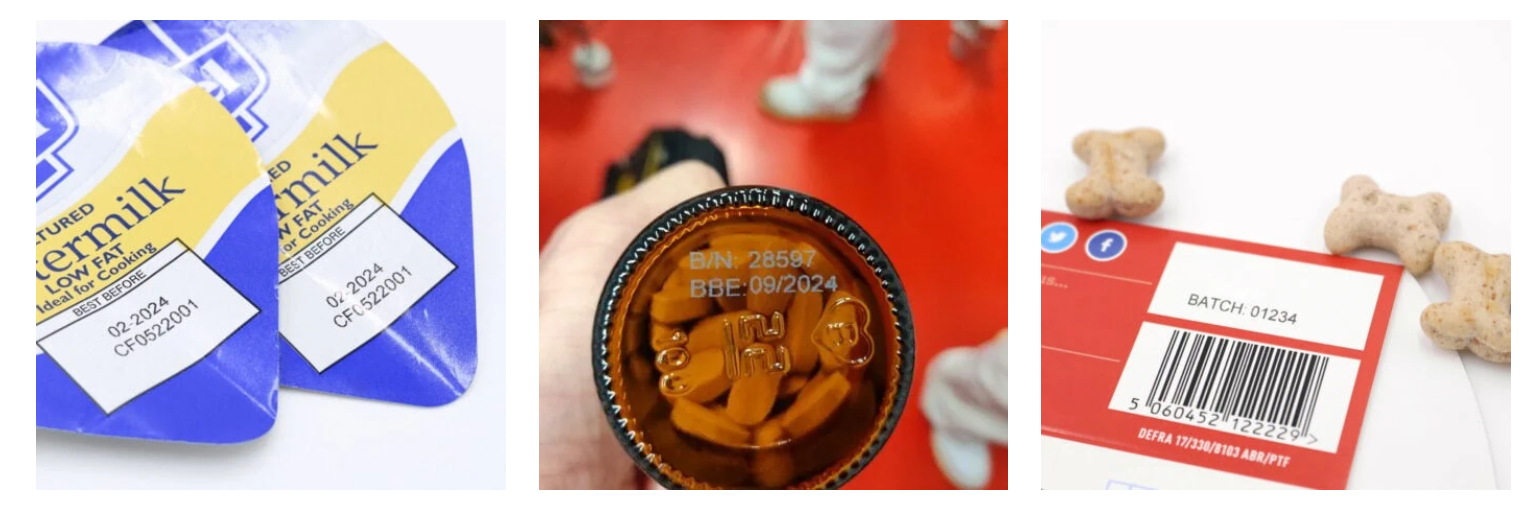

Batch codes are typically located on product packaging or directly on the product itself, depending on the industry and item type. Common placements include labels, caps, seals, or near manufacturing and expiration dates. For durable goods, batch codes may be etched onto the product, while some are embedded in barcodes or QR codes for easy traceability.

How to Start Batch Coding?

Step 1: Create Your Batch Code Number

Start by designing a unique batch code number for your batch coding process. This number should include important details such as the production date and batch sequence. Ensure that the format is clear and consistent to make tracking and quality control easier.

Step 2: Choose the Right Printing Equipment

Select the appropriate printing equipment based on your product type, packaging material, and production environment. Options include portable handheld inkjet printer, industrial inkjet printer, continuous inkjet (CIJ) printer, and thermal transfer printer. Ensure the equipment you choose produces clear and durable codes that remain legible throughout the product’s life.

How to Create Batch Code Number?

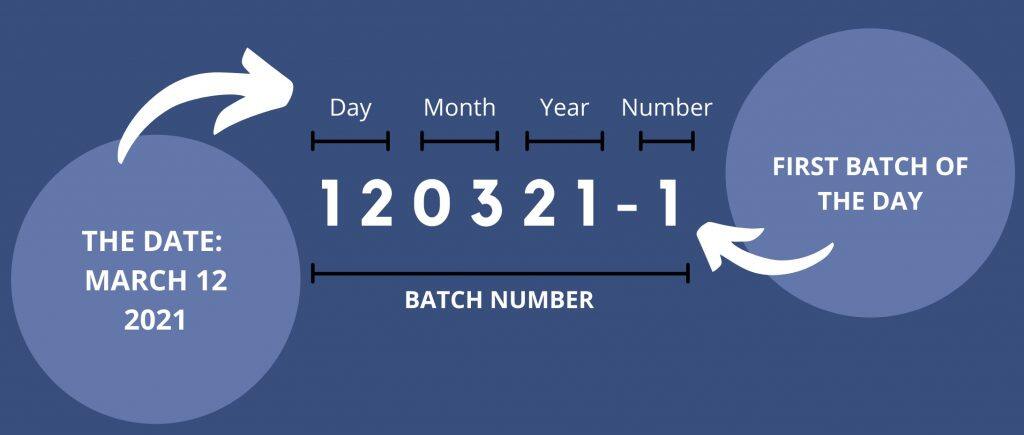

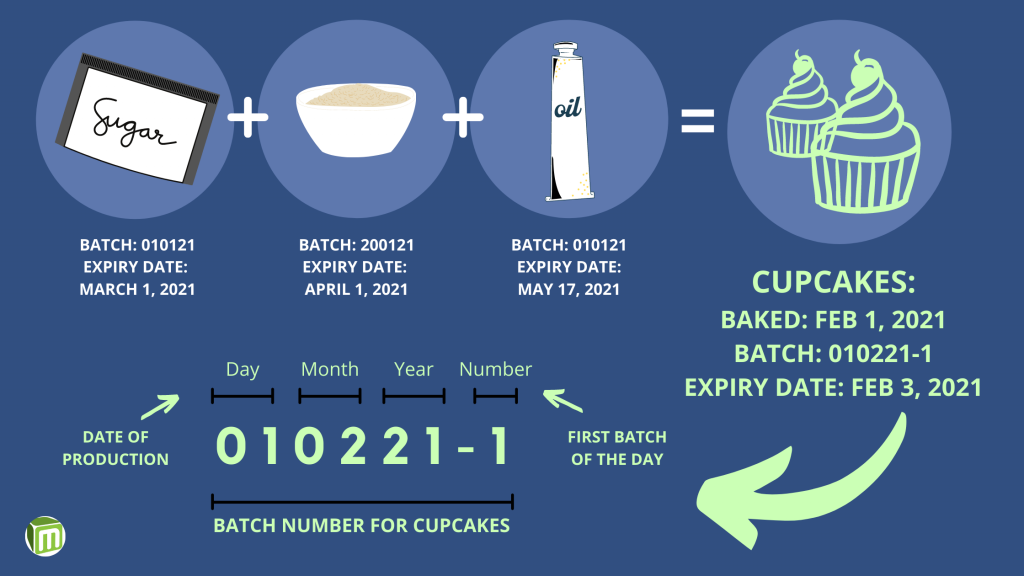

Creating a batch code number typically involves a systematic way to track production, expiration dates, or other product information. Here’s a guide to creating a batch code number:

- Define the Structure: Choose a format for your batch code that includes key details like the production date, batch or lot number, and a unique identifier (e.g., “YYYYMMDD-SEQ-ID”).

- Incorporate Key Information: Make sure the code captures essential details for tracking, such as the production line or shift.

- Standardize the Format: Use a consistent format to ensure easy identification and tracking across all products.

- Integrate with Systems: Connect the batch code system with your inventory or warehouse management tools to ensure accurate recording and easy retrieval.

- Test and Review: Check that the codes are clear and effective, and regularly review the system for any needed adjustments.

Which Type of Printer is the Best Batch Coding Solution?

- Portable Inkjet Printers: One of the best batch code printing solutions. They allow for easy small character printing on various surfaces, including hard-to-reach areas. Perfect for small to medium-sized operations that need mobility and quick setup.

- Industrial Inkjet Printers: Designed for high-volume production, these printers deliver reliable, high-quality batch codes on a range of packaging materials. They are best suited for large-scale operations requiring fast, continuous printing with minimal maintenance.

- Continuous Inkjet (CIJ) Printers: Known for their speed and precision, CIJ printers are excellent for high-speed production lines. They print on various surfaces, including non-porous materials, and are ideal for industries needing high-speed batch coding.

- Thermal Transfer Printers: These printers offer excellent print quality on flexible materials, and their prints remain legible over time, making them suitable for a variety of packaging needs.

Select the best batch coding printer based on your production volume, surface type, and code quality needs. Each type offers unique benefits suited to different operational requirements.

Conclusion

Batch codes are indispensable in modern production and supply chain management, ensuring product traceability, quality control, and regulatory compliance. From enhancing operational efficiency to building consumer trust, batch codes streamline processes across diverse industries. By implementing a robust batch coding system and selecting the right printing equipment, businesses can safeguard product integrity, optimize recall management, and maintain a competitive edge in their market. Embracing the importance of batch codes is not just a regulatory necessity but a strategic advantage for long-term success.

Ask Question

No questions and answers