Benefits of Using Handheld Inkjet Printers on Assembly Lines

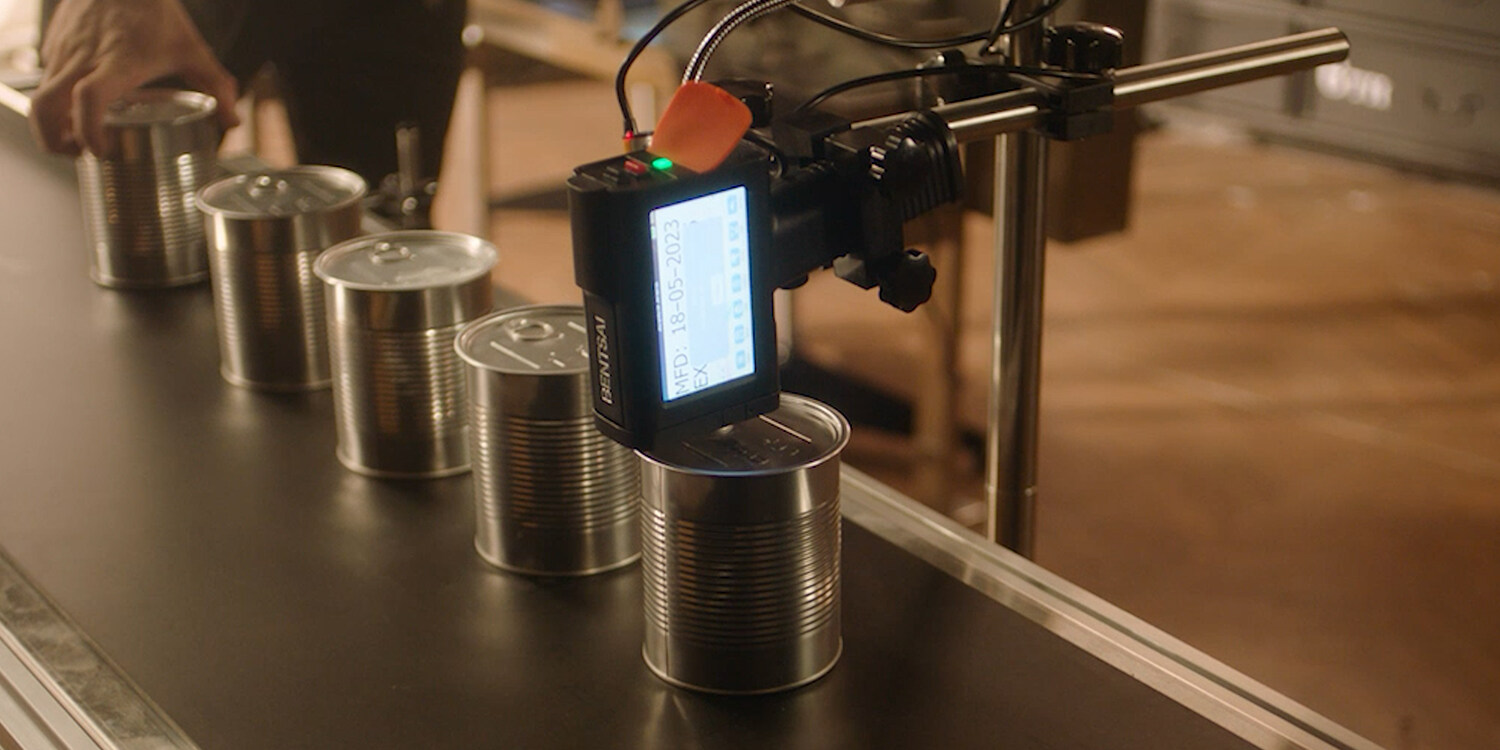

With the emphasis on production safety and the need for product management, more and more variable data needs to be printed on products, such as production date, barcode, qr code, and more others. Therefore, printing equipment that supports variable data printing is gradually becoming the preferred trend in the production industries. More and more factories are using inkjet printers for assembly lines or production lines, because of their versatility, efficiency, and ability to meet the demands of modern production processes.

What is an Inkjet Printer?

An inkjet printer, also known as an inkjet coding machine, is a type of printing device that works by spraying tiny droplets of ink onto a surface to create an image or text. It operates based on a precise mechanism where the printer's print head contains numerous small nozzles. When a print job is initiated, these nozzles release the ink droplets in a controlled manner, forming the desired pattern. This technology allows for high-resolution printing, making it suitable for a wide range of applications.

There are two main inkjet printer types: thermal inkjet (TIJ) and continuous inkjet (CIJ).

- TIJ printers heat ink in small print head chambers. The resulting vapor bubbles push ink droplets through nozzles onto the surface, enabling high quality, detailed prints. This makes them great for precision-required tasks like fine-graphic product labels.

- CIJ printers, however, generate a continuous ink droplet stream. Electrostatic charges and an electric field direct these droplets to form images or text. They're highly efficient for high-volume, industrial-scale printing on diverse materials at fast speeds, perfect for large-scale production lines.

Which Industries Need to Use Inkjet Printers for Automation?

1. Food and Beverage

The food and beverage industry has a vast array of products, from packaged snacks and bottled drinks to fresh produce. Inkjet printers can be used to print essential details like expiration dates, batch numbers, and nutritional information on food packets, and beverage containers. Industrial inkjet printers are particularly used in food and beverage companies where speed and quality are of equal significance. It ensures that the printing process doesn't slow down the high speed production lines typical in food and beverage manufacturing, while also maintaining high quality, legible prints.

2. Cosmetics and Personal Care

In the cosmetics and personal care field, inkjet printers, especially CIJ types, are crucial during packaging. They print product names, expiration dates, ingredients, and barcodes on items like lipstick tubes and shampoo bottles. Clear, precise prints enhance product appearance, influencing consumer trust.

3. Carton Packaging

In carton packaging, inkjet coding printers print variable info such as serial numbers and production dates. When cartons pass on the assembly line, the printer's photoelectric sensor triggers. It signals the printer, which then prints details like production date, batch number, barcodes, etc. within a set delay.

4. Building Materials

For the building materials industry, which includes products like cables, pipes, and construction components, inkjet printers are indispensable. They are used to spray product models, size specifications, and safety instructions. CIJ inkjet printer manufacturers often offer customized services such as nozzle setting and adjustment. This allows the printers to adapt to the unique requirements of different building materials, ensuring that the printed information is clear and durable.

5. Small-Scale Businesses

Small-scale enterprises, including local offices, boutiques, and small manufacturing units, find inkjet printers extremely beneficial. Compared to more expensive laser printers, inkjet printers, offer cost-effectiveness. They are also user-friendly, requiring minimal technical expertise to operate. Ideal for printing labels, invoices, etc., they help small operations keep costs down.

Why are Handheld Inkjet Printers More Suitable?

Compared to traditional inkjet models, handheld inkjet printers are a better choice for automation. Here's why:

-

Portability and Mobility

One of the key advantages of handheld inkjet printers is their portability. Compact and lightweight, they allow operators to move easily around the production line. This is especially beneficial for printing on large, bulky, or irregularly shaped items that are difficult to move to a stationary printer. In industries like automotive and aerospace, where parts come in various sizes and shapes, handheld printers can be effortlessly maneuvered to reach tight or hard-to-access areas. -

Flexibility for Diverse Production Needs

Handheld inkjet printers are incredibly versatile. They are ideal for both small and large-scale production runs. For small operations, they offer a cost-effective alternative to large, stationary printers, eliminating the need for significant capital investment. In high-volume production environments, they complement existing systems, enabling on-the-spot printing of additional information or quick adjustments to tasks without slowing down the production process. -

Cost-Effectiveness

Handheld inkjet printers are often more budget-friendly than their larger counterparts. Their lower initial cost makes them an attractive choice for businesses looking to streamline operations without incurring hefty upfront expenses. Additionally, their minimal maintenance requirements help reduce long-term operating costs, further enhancing their cost-effectiveness.

In Conclusion

Inkjet printers have become an essential part of modern assembly lines or production line across various industries. Their ability to print variable data accurately and efficiently meets the growing demands of production safety and product management. Among inkjet printers, handheld models offer unique advantages such as portability, flexibility, ease of use, and cost-effectiveness. These benefits make them an excellent choice for integration into automation on assembly lines. As manufacturing processes continue to evolve, handheld inkjet printers are likely to play an even more significant role in ensuring smooth, efficient, and accurate production operations.

Ask Question

No questions and answers