What is the Difference Between Lot Codes and Other Codes?

Lot code is one of the commonly used codes for product management. As many people know, there are many benefits of using lot codes. Beyond lot codes, what other codes are commonly used for product management? What are the key differences between these various codes? Understanding these aspects can enhance the effectiveness of product management practices.

SKU and Lot Code

Stock Keeping Units (SKUs) and lot codes are both crucial in inventory management but serve different functions.

What is SKU?

A SKU (Stock Keeping Unit) is a unique identifier for specific products in inventory management. Comprising letters and numbers, SKUs distinguish one item from another, enabling efficient tracking, inventory control, and sales analysis. They assist businesses in managing stock levels, identifying product variations, and streamlining the ordering process.

Difference Between SKU and Lot Code

SKU: A SKU is an alphanumeric identifier assigned to each distinct product in inventory. It aids businesses in tracking stock levels, managing product variations, and facilitating ordering and sales reporting. It is primarily used for individual item management.

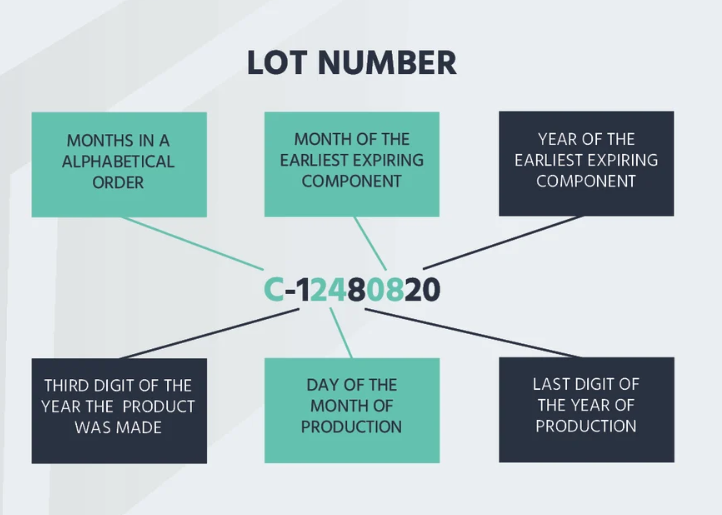

Lot Code: Conversely, a lot code identifies a specific batch of products produced together, playing a crucial role in traceability, quality control, and product recalls. This code allows businesses to trace the origin and production history of a group of items, especially in safety-critical industries like food and pharmaceuticals.

In summary, SKUs facilitate individual product identification, while lot codes are essential for batch tracking, ensuring the quality and safety of grouped items.

Serial Number and Lot Code

Both serial numbers and lot codes are vital for product identification.

What is Serial Number?

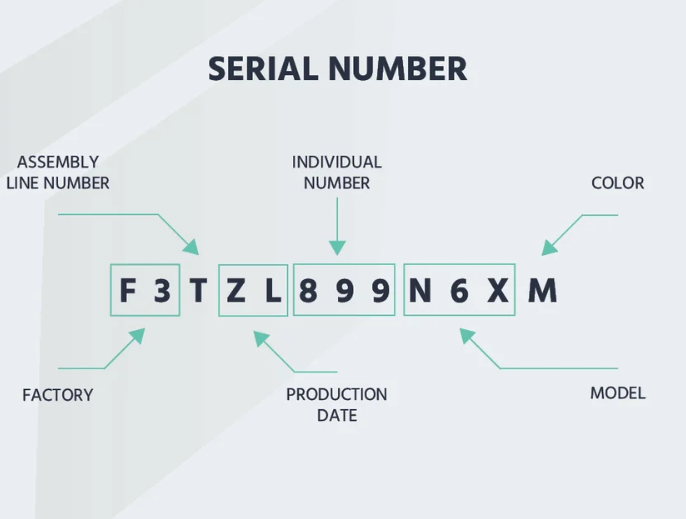

A serial number is a unique identifier assigned to individual items, distinguishing them from others of the same type. Commonly used in manufacturing and retail, serial numbers aid in tracking, inventory control, warranty management, and counterfeit prevention. They are essential for quality assurance and provide a history for service and recalls.

Difference Between Serial Number and Lot Code

Serial Number: A serial number uniquely identifies an individual item, facilitating tracking, warranty claims, and fraud prevention by providing a historical record of the item's lifecycle.

Lot Code: A lot code identifies a specific batch of products produced together and is crucial for traceability, quality control, and product recalls.

In summary, serial numbers focus on individual identification, while lot codes manage groups of items for batch tracking.

How to Print These Codes

Effective mainstream solutions for printing lot codes, SKUs, and serial numbers include:

1. Handheld Inkjet Printers

Handheld inkjet printer - one of the best solutions for printing these codes. Normally featuring adjustable print heights from ½ inch to 4 inches, these printers accommodate diverse coding needs. They can print directly on various surfaces, making them ideal for on-the-go applications in settings like warehouses and manufacturing. This portability allows users to work without being constrained to a specific spot, enhancing efficiency and flexibility.

2. Label Makers

Affordable and compact, label makers are compatible with various systems, making them versatile for different applications. They enable quick and customizable label creation without the need for ink or toner, making them cost-effective. User-friendly and straightforward, they are excellent for small businesses that require efficient labeling solutions.

3. Laser Printers

Laser printers provide high-speed printing of SKUs and serial numbers with crisp, professional quality. They are well-suited for larger volumes, making them a cost-effective option for businesses that need to print large batches of codes. Their ability to handle various media types adds versatility to printing applications.

4. Thermal Transfer Printers

This option produces durable, long-lasting labels for SKUs and lot codes. Ideal for logistics and inventory management, these printers ensure resistance to fading and smudging, making them perfect for labels that need to withstand various conditions.

These solutions cater to different printing needs, ensuring efficient and effective labeling for inventory management.

Conclusion

In summary, lot codes, SKUs, and serial numbers are essential for effective commodity management and enterprise production. Lot coding enables traceability and quality control, while SKUs facilitate efficient inventory tracking and sales analysis. Serial numbers provide unique identification for individual items, crucial for warranty management and counterfeit prevention. Together, these coding systems enhance operational efficiency and ensure compliance, making them vital for businesses aiming to optimize their product management practices.

Ask Question

No questions and answers