What is a Lot Code and Why is It Needed?

Lot codes are crucial in industries like manufacturing and food production, ensuring traceability, aiding recalls, and improving quality control. They optimize inventory management, reduce waste, and support regulatory compliance. By providing transparency, they also enhance consumer trust, playing a key role in quality assurance across sectors.

What is a Lot Code?

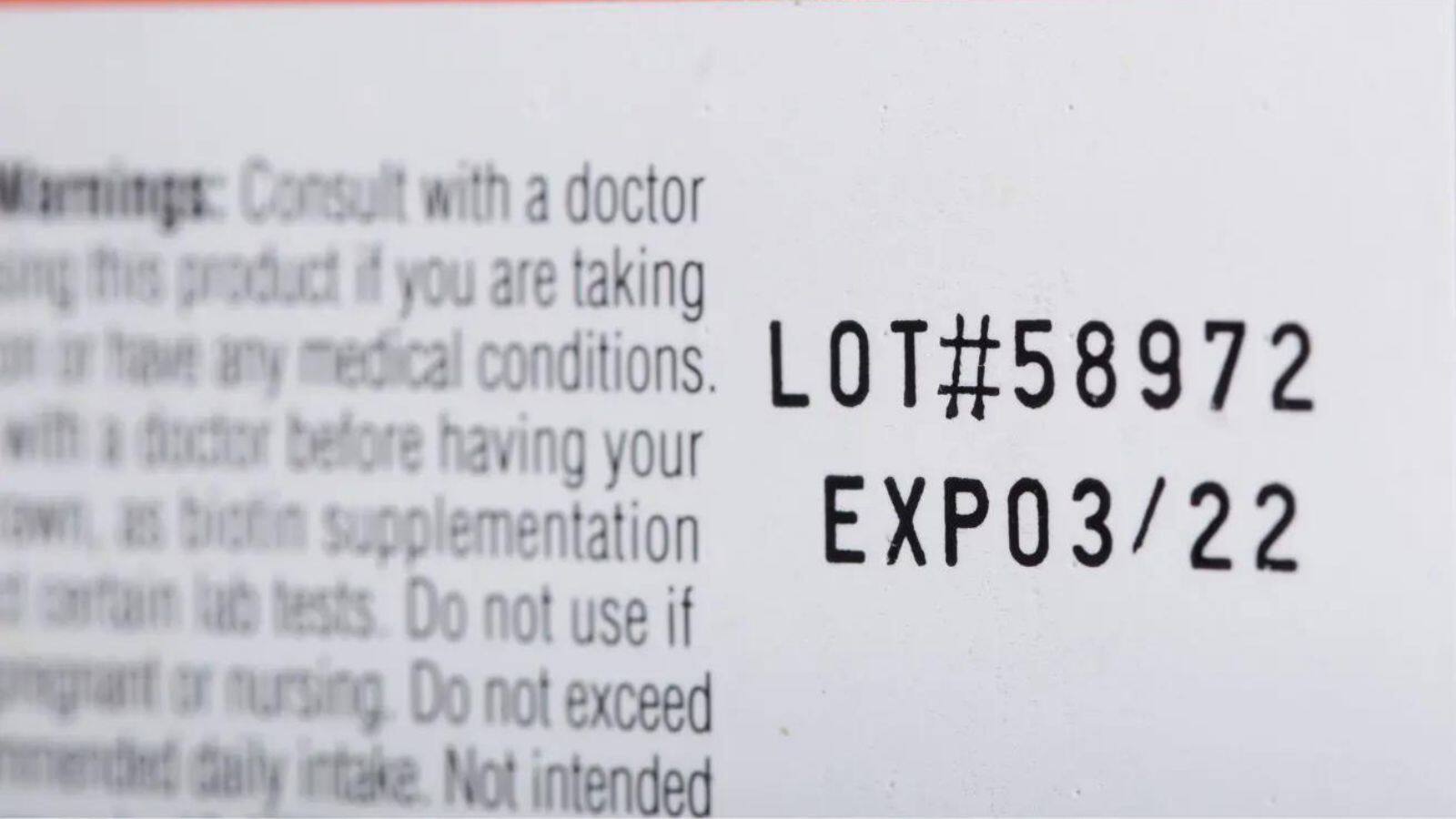

A lot code, also known as a lot number, is a unique identification code assigned to a specific batch of products produced under similar manufacturing conditions. This code helps in track and manage entries by linking products to their production details, such as the date of manufacture and the materials used. Lot codes are essential for traceability, quality control, and regulatory compliance, enabling businesses to efficiently monitor and recall products if necessary.

Why do Manufacturers Need to Use Lot Codes?

Lot codes are crucial for several reasons, making them an important aspect of product management across various industries:

- Traceability: Lot codes allow manufacturers to trace products back to their specific batches, which is essential during recalls. This traceability protects consumers by enabling quick identification and removal of potentially unsafe products from the market.

- Quality Assurance: By linking products to their production batches, lot codes facilitate effective quality control. They help identify trends in defects or issues within specific lots, allowing manufacturers to make necessary improvements to processes or materials.

- Regulatory Compliance: Many industries, especially food and pharmaceuticals, are bound by strict regulations regarding product safety and tracking. Lot codes meet these regulatory requirements, ensuring that companies can provide documented evidence of compliance.

- Inventory Management: Lot codes enhance inventory tracking, helping businesses monitor stock levels, manage expiration dates, and optimize product turnover. This efficiency reduces waste and improves overall supply chain management.

- Consumer Trust: By providing a clear system for identifying and recalling products if necessary, lot codes play a significant role in building consumer trust. Shoppers feel more secure knowing that the products can be traced back to their origin.

Overall, lot codes are essential for ensuring product safety, enhancing quality control, ensuring compliance with regulations, and building consumer confidence, all of which contribute to the efficiency and effectiveness of supply chain operations.

When is Lot Coding Required?

Lot codes should be used in various situations, particularly when tracking products throughout the manufacturing and distribution processes is essential. Here are key instances when lot coding is necessary:

- Manufacturing: During the production of goods, lot codes are applied to batches of products to ensure traceability. This is critical for identifying specific lots in case of quality issues or recalls.

- Quality Control: Lot codes need to be used when monitoring product quality. They help manufacturers link any defects or problems to a specific batch, facilitating investigations and improvements.

- Inventory Management: Whenever products are received, stored, or shipped, lot codes should be utilized. This assists businesses in tracking expiration dates, managing stock levels, and ensuring that older products are sold first, reducing waste.

- Regulatory Compliance: Industries like food and pharmaceuticals require lot coding to comply with regulations. Lot codes ensure that companies can provide documentation and evidence of safety standards and traceability when needed.

- Product Recalls: In the event of a safety concern, lot codes are crucial for quickly identifying and recalling affected products from the market. This minimizes health risks for consumers while protecting brand reputation.

- Consumer Communication: When products are sold to consumers, especially in the food and drug sectors, lot codes facilitate transparency. Consumers can reference these codes to verify the safety and quality of products they purchase.

In summary, lot coding is essential in manufacturing, quality control, inventory management, regulatory compliance, product recalls, and consumer communication, helping ensure the safety and quality of products throughout their lifecycle. For those looking to implement lot coding efficiently, lot coding printers can be invaluable tools.

Conclusion

In summary, lot coding is essential for ensuring traceability and quality assurance across various industries. By using lot codes during manufacturing, quality control, and inventory management, businesses can monitor products effectively, comply with regulations, and facilitate quick recalls in case of safety concerns, thereby protecting consumers and building brand trust. Additionally, lot codes promote transparency, allowing consumers to verify product quality and safety. Overall, implementing lot coding is vital for operational efficiency and product integrity, and investing in lot coding printers can enhance these processes significantly.

Ask Question

No questions and answers