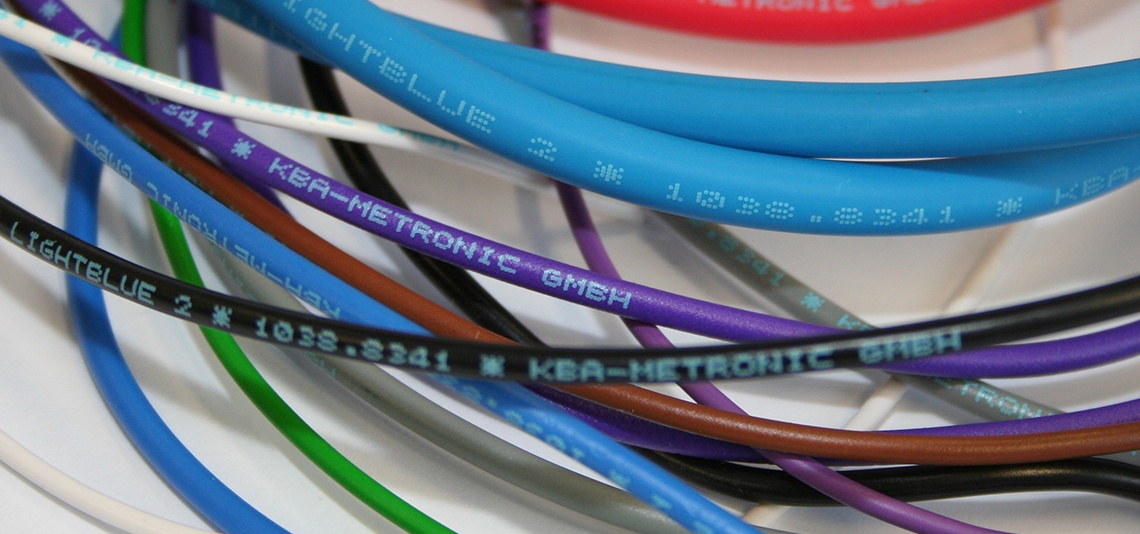

Where to Find a Reliable Lot Code Printer for Cables and Wires?

Accurate and durable labeling on cables and pipes is essential for safety, compliance, and operational efficiency. Proper markings facilitate easy identification, traceability, and maintenance, ensuring safe installations and adherence to standards. This article explores the significance of marking cables and pipes, what information is required, various printing technologies, and the best Bentsai handheld printers for the job.

What Information is Generally Required to be Marked on Cables and Pipes?

Labeling on cables and pipes is not just about putting some text; it involves detailed and specific information that ensures the products meet regulatory standards and can be easily identified and traced. Here are the essential details typically required:

- Manufacturer Information: Name or logo of the manufacturer.

- Product Specifications: Size, type, and material of the cable or pipe.

- Date Codes and Batch Numbers: For traceability and quality control.

- Compliance Marks: Standards and certifications met by the product.

- Safety Information: Warnings or safety instructions.

- Usage Instructions: Installation or handling guidelines.

Why Is Cable and Pipe Marking Important?

Cable and pipe marking is crucial for safety, compliance, traceability, and operational efficiency. Mainly reflected in these 4 aspects:

- Safety and Compliance: Ensures adherence to industry standards, such as EN 50575, UL, and CSA, preventing hazards and guaranteeing that cables meet specifications.

- Traceability: Facilitates the identification and tracking of cables throughout their lifecycle.

- Operational Efficiency: Reduces errors and saves time during installation and maintenance.

- Quality Control: Enables manufacturers to perform selective testing and manage recalls efficiently.

- Inventory Management: Helps in organizing and managing stock effectively.

- Brand Protection: Ensures product authenticity and helps in combating counterfeiting.

What Printer Can Print on Cables and Pipes?

Before introducing the different types of printers suitable for printing on cables and pipes, it's important to understand the various materials these items are made from and how this affects the choice of printer.

Types of Material Surfaces for Cables and Pipes

Cables and pipes can be made from various materials, including PVC, metal (copper, steel, aluminum), rubber, polyethylene, and other synthetic materials. Each material has unique characteristics that require specific printing technologies for effective labeling.

Now, let's look at the different types of printers that can effectively print on these surfaces:

Types of Printers That Print on Cables and Pipes

1. Continuous Inkjet (CIJ) Printer:

CIJ printers use a continuous stream of ink droplets to print. The technology is based on electrostatic charging, where droplets are deflected to create characters as the substrate moves past the printhead.

Pros:

- High-speed printing

- Suitable for high-volume production

- Effective on most materials, including PVC and metal

Cons:

- Requires regular maintenance

- Higher initial costs

2. Handheld Inkjet Printer:

Handheld inkjet printers use thermal inkjet technology, where tiny resistors create heat, causing the ink to vaporize and form a bubble. This bubble pushes the ink out of the nozzle onto the substrate.

Pros:

- Portable and easy to use

- Versatile for different surfaces, including PVC, polyethylene, metal, and rubber

- Less initial investment compared to CIJ

- High quality printouts with endless font types

Cons:

- Print slower compared to CIJ

- Ink cartridges could be costly over time

3. Laser Printer:

Laser printers use focused laser beams to mark the surface of the material. The laser interacts with the material to create permanent marks without the need for ink or other consumables.

Pros:

- Permanent marking with high precision

- No ink needed

- Suitable for various materials, especially metals and plastics

Cons:

- Higher initial cost

- Not suitable for all materials

4. Thermal Transfer Printer:

Thermal transfer printers use heat to transfer ink from a ribbon onto the surface of the substrate. The technology ensures high-quality, durable prints.

Pros:

- High-quality, durable prints

- Suitable for labeling cables with sleeves

- Effective on most synthetic materials

Cons:

- Slower than CIJ

- Requires consumables like ribbons

5. Dot Peen Marking Systems:

Dot peen systems use a pin to create indentations on the surface of the material. This method is durable and creates permanent marks.

Pros:

- Durable and permanent marking

- Suitable for metal surfaces

Cons:

- Not suitable for non-metal materials

- Can be noisy

Each of these printing technologies offers unique advantages and is suitable for different types of materials used in cables and pipes. Understanding these differences can help you choose the best printer for your specific application needs.

Which Bentsai Handheld Inkjet Printer is Best Suited for Marking on Cables and Pipes?

While all Bentsai printers are capable of printing batch codes, date codes, and logos on pipes and wires, we highlight three models that use solvent-based ink for versatile applications on both porous and non-porous surfaces.

1. Bentsai B2 Handheld Printer Gun

Price: $530

Print Height: Up to 12.7mm

Resolution: 300 DPI or 600 DPI optional

Print Speed: 30m/min

Pros:

- High resolution and speed

- Positioning aid for precise printing

Cons:

- No variable data printing feature

- Print size is limited compared to those machines that print up to 1 inch

Best Suited For: Small character printing within half an inch and users not needing variable data printing.

2. Bentsai B35 Handheld Inkjet Printer

Price: $700

Print Height: Up to 25.4mm

Resolution: 300 DPI or 600 DPI optional

Print Speed: 15m/min

Pros:

- Larger font printing for broader applications

- Variable data printing for dynamic tasks

- Positioning aid for precise printing

Cons:

- Resolution not as high as the Bentsai B2 but still meets daily needs

Best Suited For: Versatile applications requiring larger fonts and variable data printing.

3. Bentsai B10 Mini Inkjet Printer

Price: $329

Print Height: Up to 12.7mm

Resolution: 300 DPI

Print Speed: 30m/min

Pros:

- Compact and lightweight, easily fits in a pocket

- WiFi connection and app-controlled for easy operation

- Attachable roller plate for small areas like cables

Cons:

- No positioning aid, can be difficult to print on precise objects

Best Suited For: Portable, quick printing on small surfaces, ideal for on-the-go tasks.

Do You Need Help Choosing the Right Batch Code Printer for Pipes and Wires?

Choosing the right batch code printer for pipes and wires is essential to ensure clear, durable, and compliant markings. Bentsai offers a range of solutions designed specifically for printing on various materials, including PVC, metal, and rubber, commonly used in pipes and wires. Our printers are versatile, reliable, and easy to integrate into your workflow.

For those seeking marking solutions for substrates beyond cables and pipes, feel free to contact our team for tailored advice to meet your specific printing needs.

Email: support@bentsaishop.com

WhatsApp: +86 18928097992

Let us help you find the perfect printer to enhance your operational efficiency and product traceability.

Ask Question

No questions and answers